Onderzoeksproject

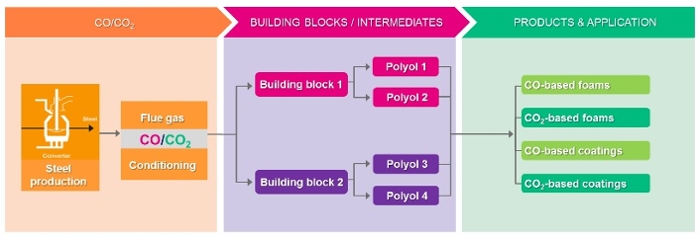

Carbon4PUR | Turning industrial waste gases (mixed CO/CO2 streams) into intermediates for polyurethane plastics for rigid foams/building insulation and coatings

What would be the environmental performance of the Carbon4PUR technology at industrial scale in the future?

- Looptijd

- 2017 - 2020

- Financiering

-

European Union’s Horizon 2020

European Union’s Horizon 2020

- Partners

14 partners from 7 European countries are involved in the Carbon4PUR project.

All participating partners in the Carbon4PUR consortium are shown on the project website.

Short abstract

Carbon4PUR project aims at transforming steel mill gases into polyurethanes for rigid foams/building insulation and coatings. Ex-ante Life Cycle Assessment (LCA) has been applied early in Research and Development (R&D) to guide the Carbon4PUR technology development towards improved environmental performance levels.

Project description

The Carbon4PUR consortium is developing a new process for the production of value-added chemicals based on direct chemical steel mill gas mixture conversion. This process will allow to avoid expensive conventional steel mill gas purification and conditioning methods, significantly reducing the carbon footprint and contributing to high monetary savings. One of the goals of the Carbon4PUR project is to provide an environmental assessment of the new technology early in Research and Development (R&D).

Identification of possible environmental impacts early in the technology development is essential as it allows to redirect R&D towards improved environmental performance levels with relatively low costs and high

impact, which is difficult to do at later stages of the technology development when the technology is close to commercialization. Ex-ante Life Cycle Assessment (LCA) has been used to guide the Carbon4PUR technology development towards decreased environmental burdens. LCA has been performed for the Carbon4PUR technology developed at laboratory scale and for the up-scaled technology. The environmental impact results of the novel technology have been compared to the impact results of the conventional technology. The results of this study will be used by the Carbon4PUR consortium as a guidance for the Carbon4PUR technology development.

The Institute of Environmental Sciences (CML) has an extensive research experience in the development of the decision making tools on sustainable production and consumption. One of the main focuses of CML is the development of ex-ante LCA methodology.

Deliverable 6.2. Baseline LCA on conventionally produced polyol/PUR and steel mill gas treatment.