Erik Danen part of NWO Perspectief grant for organ-on-chip

A consortium of research groups, including that of LACDR professor Erik Danen, will use an NWO Perspective grant of nearly five million euros to build a universal standard for organ-on-chip models. They aim to stimulate the application of these chips in the biomedical and pharmaceutical industry. Danen and colleagues will use the technology developed to study fibrosis, a serious, common disease for which there is no good treatment.

SMART

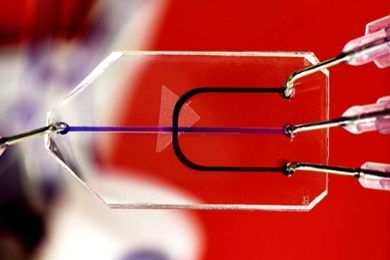

In an organ-on-chip model, minuscule human tissues are connected via micro-sized fluid channels. This allows scientists to mimic organs, study diseases, and test the effect of medicines or food ingredients. At the moment, the chips are mainly used by academic researchers. Large-scale use by pharmaceutical companies is not yet taking place, because the various types of chips, with their complex control of fluid flows, are difficult to fit into the pharmaceutical industry.

This consortium of 8 universities, already united in hDMT, now wants to change this. Together with 21 companies, 3 knowledge institutions and 2 foundations they will develop a standardised and modular platform: 'SMART Organ-on-Chip'. On 10 March, they received a Perspectief grant for this, consisting of 3.4 million euros from the Dutch Research Council (NWO) and an investment of 1.4 million euros from the participating companies and foundations.

Due to the selected cookie settings, we cannot show this video here.

Watch the video on the original website orLEGO bricks

The grant brings together a broad multidisciplinary group of scientists. This cluster is essential for the ambitious research, together with industrial partners, from manufacturing industry to end-users. To standardise the chips but at the same time allow flexible use, the researchers are building a so-called docking plate. This has an industrial standard size, which contains the fluid channels and the electronics. Advanced tissue chips with organs and technical chips with innovative fluid pumps, actuators and sensors can then be clicked onto the system like LEGO bricks.

The whole system will fit into the standard pipetting robots and automated microscopes used by industry. Moreover, it will be an 'open technology', so that other companies can also add their own applications to the SMART platform.

Studying scars

For the tissue chips, the participants will make great strides in reproducing human organs in detail. The developed models will then be used to study fibrosis. This serious disease is common, but so far, there hasn't been a good treatment for it.

Danen: ‘Fibrosis is actually an out-of-control healing process that occurs in the case of chronic tissue damage, infection or tumour growth. Changes in connective tissue cells, the extracellular matrix and various immune cells occur, and permanent scar tissue is formed in the organ. The complexity of the process has so far prevented a good model for studying fibrosis.’

Danen's research group hopes to change that. ‘We build miniature models of tissues in which we study aspects of cancer and fibrosis. The organ-on-chip models we will develop in this Perspectief programme will enable us to map the dynamics of this type of disease process much better and to test candidate drugs.’