Irene Groot receives Vidi grant: looking at catalysts at atomic scale

Catalysts are indispensable in everyday life. We know what they do and more or less how they do it, but we still lack a fundamental understanding about their functioning at an atomic scale. Therefore, Irene Groot from the Leiden Institute of Chemistry develops new measuring techniques to unravel the processes at an anatomic level. For this, she received a Vidi grant.

Working horse of chemics

Catalysis is the working horse of the chemical industry. Ninety percent of all materials and chemicals we use are produced via catalysis. A catalyst is a chemical compound that affects the rate and selectivity of a chemical reaction, without being consumed itself. The primary objectives of catalysis are to enhance the reaction rate and to yield the desired products with high stability. The best-known example of catalysis is the automotive catalyst that converts toxic gases into less harmful ones.

Trial-and-error

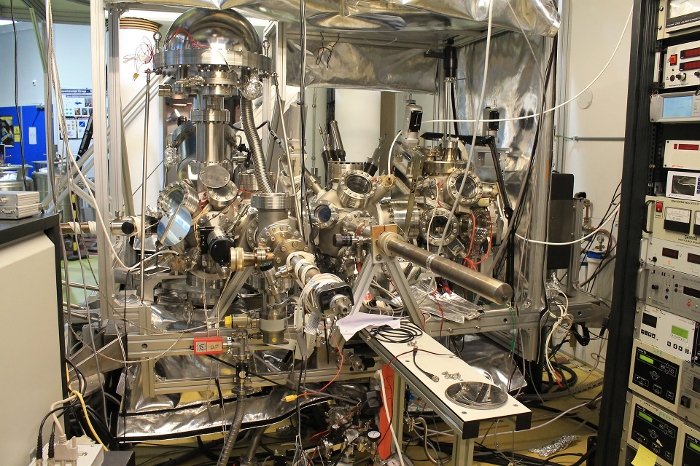

Despite years of research it is yet not possible to develop catalysts from a rational design. ‘Catalysts are still produced through trial-and-error’, tells Groot. ‘This stems from the fact that most techniques to invest catalysis at an atomic scale cannot perform at the typical industrial conditions, like high temperatures and pressure. That is why we mainly have knowledge about catalysis in circumstances that are different than in practice. ' To be able to investigate catalysis at the atomic scale during the actual chemical reaction, de Groot has developed new instrumentation. ‘With these special microscopes I investigate industrially and societally relevant chemical processes. Examples are the removal of sulfur from oil to prevent acid rain and the production of clean artificial fuels to reduce the release of CO2 into the atmosphere.

Sustainable

Groot hopes with the Vidi grant she can unravel the exact reaction mechanisms of the reactions under study in relation to the atomic-scale structure of the catalytic surface. ‘When we have a fundamental understanding of catalysis at the atomic scale, we can start to design catalysts instead of producing them via trial-and-error. When making use of better catalysts in the chemical industry and in our cars, we can make these vital chemical processes cleaner, putting less strain on the environment. Furthermore’, Groot adds, ‘new and better-performing catalysts are vital for the transition from a fossil-fuels-based economy to a sustainable economy.’

Special technique

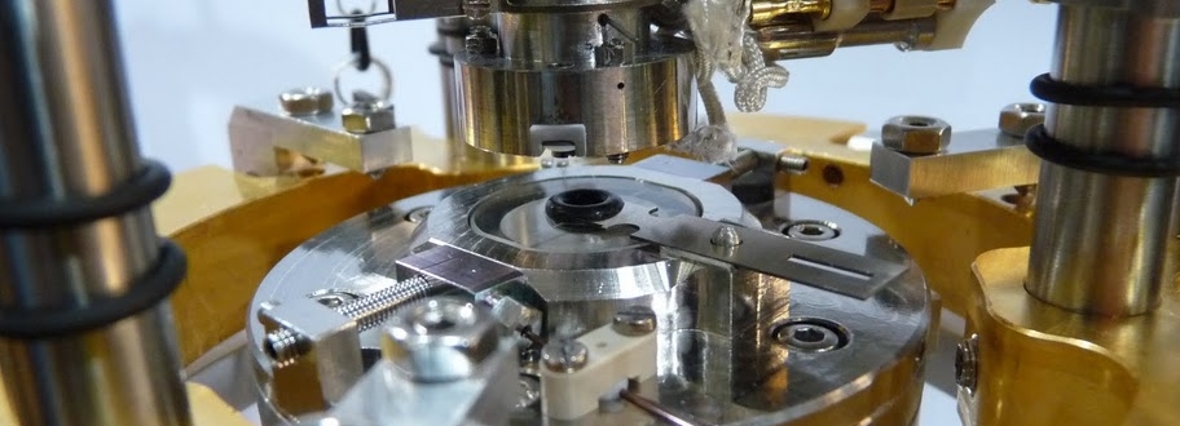

To study the structure of a catalytically active surface, the research group used advanced microscopy and spectroscopy. They do this with actual chemical reactions under industrially relevant conditions. The special microscopes obtain atomic-scale information simultaneously with information about the activity of the catalyst. Hereby, the researchers can observe structural changes on the catalyst’s surface at the moment that they also observe a change in activity.

Headerphoto: inside of the setup where the special Scanning Tunneling Microscope (STM) can be seen.

VIDI

The Vidi grants are awarded by the The Netherlands Organisation for Scientific Research (NWO). The financial instrument is intended for successful postdoc researchers who have already set up their own research line and now want to start their own research group. With the grant worth 800,000 euros they can appoint researchers and boost their own scientific career. A total of 571 researchers submitted an application this Vidi round. 86 of these have been honoured. That comes down to an awarding percentage of 15%.