Tjerk Oosterkamp Lab - Microscopy and Quantum Mechanics at milliKelvin temperatures

Vibration Isolation

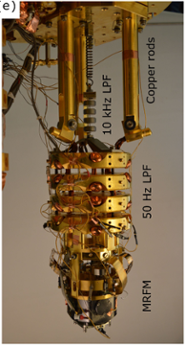

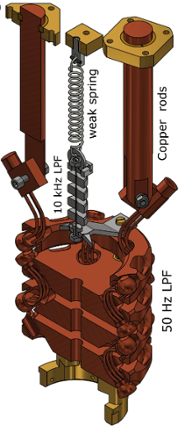

To be able to measure small forces or small deviations from Boltzmann, the external vibrations at the resonance frequency must be very low. To achieve this, we have developed a very soft vibration isolation system and combine it with several other measures to reduce vibrations in our dilution refrigerators. We are continuously working to improve its performance. Next we hope to lower its temperature from 12 mK to 2 mK and to reduce vibrations at lower temperatures.

We have developed a vibration isolation system [1] with high thermal conductance for a cryogen-free dilution refrigerator. It enables us to do improved experiments for nano-MRI and is essential for our quantum experiments.

If we assume that there is an end to quantum mechanics, and that the collapse of the wave function is a real physical process, then we may have to add a term to the regular quantum Hamiltonian that causes this collapse. If this assumption is correct, this could be an entirely new force of nature, which should obey the following rules: it must be non-unitary since information is destroyed, and it must be random, since the measurement outcome after collapse, according to previous experiments, is random.

In other words, it is a noise source. This hypothesis is studied in spontaneous wavefunction collapse theories. When we cool our resonator down to millikelvin temperatures, we see the noisy Brownian motion due to the thermal noise decrease. If the spontaneous collapse theories are correct, then we might start to see an additional noise source on top of the thermal noise. In other words, we can test how much additional noise there is by measuring the temperature and the noise of the mechanical resonator.

There is one problem with this approach, which is that additional noise is expected to some degree: vibrations from people, pumps, traffic and builders all enter the cryostat and are forces of non-thermal mechanical noise. Another source of mechanical interference, is our pulsed cooler that we use to cool to 4 Kelvin and the circulation pumps for the dilution refrigerator.

Thus, by measuring non-thermal mechanical noise, we can only put an upper bound on the spontaneous collapse of the wavefunction. And the challenge is then to lower this upper bound by, apart from lowering the temperature and damping of our force sensor, by employing various strategies for vibration isolation.

We are currently using a dissipative passive damper at the 4K plate in our dilution refrigerator, as well as a passive vibration isolation system without extra dissipation in the form of gilded copper masses and springs at the coldest plate.

We are working on two different kinds of active vibration isolation, which an undergraduate student could contribute to:

- At room temperature we try to compensate for the vibration of the pulsed cooler: in our approach we try to cancel the vibrations induced by the pulsed cooler by moving lead masses in such a way that they counteract the forces of the cooler. The hardware for this project is finished, and consists of seven actuators that move either 20 kg or 40 kg of lead vertically or horizontally. The project now requires the implementation of an optimal control algorithm to drive the masses.

- At the coldest plate: a single (or two separate) piezo-elements could be used to measure and to cancel vibrations at the coldest plate, before they enter the mass-spring isolation system. This setup is still in the early stages of development and requires design work and feasibility testing. It is a simpler system and could be a testing ground for the control algorithm of (1).

References

[2] Atomic resolution scanning tunneling microscopy in a cryogen free dilution refrigerator at 15 mK, A.M.J. den Haan, G.H.C.J. Wijts, F. Galli, O. Usenko, G.J.C. van Baarle, D.J. van der Zalm, T.H. Oosterkamp, Review of Scientific Instruments 85 (2014) 035112, https://dx.doi.org/10.1063/1.4868684